| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | Wuxi Slast/Sylaith Special Steel Co., LTD |

| Certification : | MTC |

| Payment Terms : | T/T |

| Supply Ability : | 100+ton/tons+month |

| Delivery Time : | 7-15 days or as requirements |

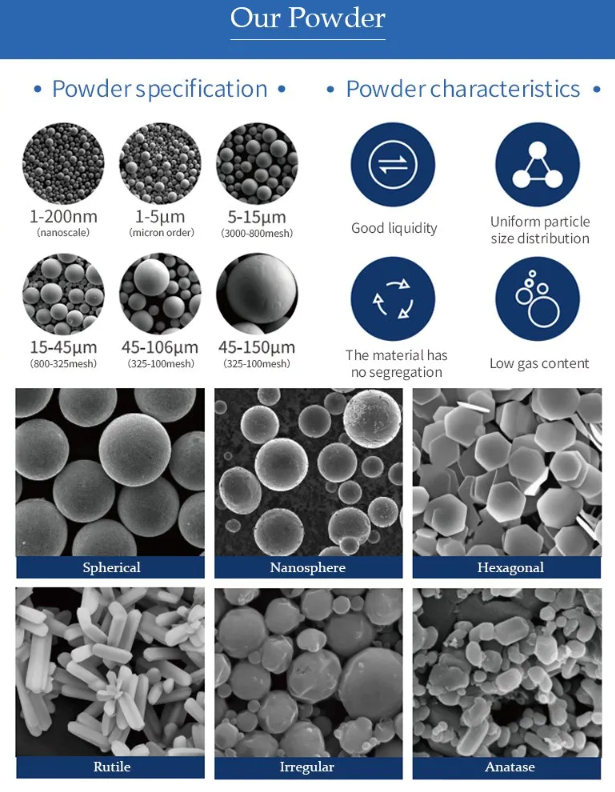

Source high-performance Water Gas Atomized and Electrolytic Ultra Fine Pure Copper Powder for your advanced industrial needs. This premium nano and fine copper powder boasts purity levels >98% and is available in a distinctive red-orange color. Produced using advanced atomization technologies like the Plasma Rotating Electrode Process (PREP), it guarantees high sphericity (>95%), excellent flowability, and no hollow particles. Ideal for 3D Printing (Additive Manufacturing), Laser Cladding, Hot Isostatic Pressing (HIP), and Thermal Spraying, this copper powder ensures superior results in creating conductive, durable, and high-density components. With a customizable particle size range and a production capacity backed by rigorous quality control, it is the perfect material for aerospace, automotive, and general manufacturing sectors.

| Parameter Category | Details |

|---|---|

| Product Name | Ultra Fine / Nano Copper Powder |

| Production Method | Water/Gas Atomization, Electrolytic, Plasma Rotating Electrode Process (PREP) |

| Purity | >98% |

| Shape | Spherical |

| Color | Red and Orange |

| Particle Size | 15-45 microns, 45-105 microns, 45-150 microns (Customizable) |

| Key Properties | High Sphericity (>95%), No Hollow Powder, Good Fluidity, High Density, Narrow Particle Size Distribution |

| Oxygen Control | Low oxygen increment, effectively controlled within specified limits (e.g., 50-100ppm for various metals) |

| Packaging | Plastic in Carton or Iron Drum |

| Production Capacity | 5000 kg/Year |

The high-quality spherical copper powder is primarily produced via the Plasma Rotating Electrode Process (PREP):

| Weight | Packing |

|---|---|

| <25KG | By foil-alum bag/pap/bottle |

| ≥25kg | 25kg/drum/bag or as requested |

Store in tightly closed containers in a dry, well-ventilated place. Vacuum packaging available for optimal preservation.

A1: While both are atomization methods, PREP (Plasma Rotating Electrode Process) typically produces powder with higher sphericity, fewer satellite particles, and virtually no hollow powder due to its centrifugal force-based mechanism, resulting in better flowability and packing density for critical applications like 3D printing.

A2: A spherical shape is critical for applications like 3D printing and Metal Injection Molding (MIM) because it ensures excellent powder flowability. This allows for uniform spreading and packing, leading to higher density, better surface finish, and more consistent mechanical properties in the final product.

A3: Yes, our production process allows for effective control over the particle size distribution. We offer standard ranges like 15-45µm but can customize the size to meet specific application requirements, ensuring optimal performance for your process.

A4: The low oxygen content is achieved through an inert gas atmosphere during the atomization and subsequent two-step treatment processes. Low oxygen is vital as it prevents oxidation, which can degrade the powder's electrical conductivity, solderability, and overall mechanical performance in the final component.

A5: Our annual production capacity is 5000 kg. Standard packaging is in plastic bags placed within cartons or iron drums to ensure the powder is protected from moisture and contamination during transport and storage.

|